How Expert Commercial Refrigerator Repair Can Boost Your Company Effectiveness

How Expert Commercial Refrigerator Repair Can Boost Your Company Effectiveness

Blog Article

The Ultimate Overview to Commercial Refrigeration Fixing: Essential Steps and Typical Problems Discussed

Usual Business Refrigeration Problems

When operating business refrigeration systems, companies might run into a number of common concerns that can affect the efficiency and capability of the equipment. One widespread issue is improper temperature level regulation. Rising and fall temperatures within the refrigeration unit can cause food spoilage, boosted energy intake, and compromised top quality and safety requirements. This issue commonly stems from a damaged thermostat, improper door seals, or insufficient insulation.

Another common problem is refrigerant leakages. Leakages can result from deterioration, poor setup, or manufacturing issues. If left unaddressed., reduced cooling agent degrees not just prevent the device's air conditioning capacity however can additionally lead to compressor failing.

In addition, ice build-up on evaporator coils is a frequent concern. Ice accumulation restricts airflow, causing the unit to function harder and eat even more power. Routine cleansing and maintenance of the coils can help prevent this issue.

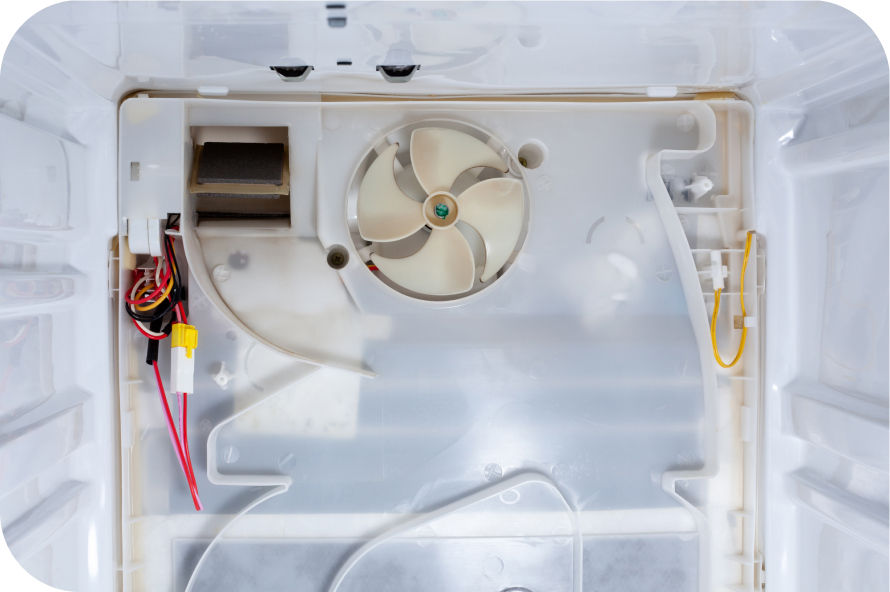

Important Tools for Repairing Refrigeration Devices

Making use of the ideal devices is crucial for effectively fixing business refrigeration systems to make sure ideal performance and longevity. A collection of crucial devices is vital for service technicians to identify and take care of problems quickly. Among the fundamental devices needed are manifold evaluates for checking cooling agent stress, refrigeration wrenches for tightening up or loosening fittings, a multimeter for testing electrical parts, and leakage discovery devices such as electronic leak detectors or ultraviolet dye packages. In addition, vacuum pumps are important for evacuating air and wetness from the system before cooling agent recharge. commercial refrigerator repair.

In the realm of specialized tools, tube cutters and flaring devices are necessary for working with copper tubing, while a recuperation machine is necessary for securely removing refrigerants. A temperature weapon can be beneficial for swiftly determining temperature differentials within the device. Purchasing top notch tools not just boosts effectiveness during fixings however likewise contributes to the precision and dependability of the upkeep job carried out on business refrigeration systems.

Step-by-Step Troubleshooting Guide

The next action is to check the temperature level controls and settings to ensure they are functioning appropriately. This consists of checking the thermostat, thaw timer, and various other control systems to verify that they are regulating the temperature level as meant. Modifications or replacements may be needed. if any type of disparities are discovered.

Subsequently, the technician must analyze the condenser and evaporator coils for dust or debris buildup, which can hinder proper air conditioning. Cleaning these parts can typically resolve concerns with temperature guideline and performance.

Preventative Maintenance Techniques

Applying normal preventative maintenance procedures is vital for guaranteeing the longevity and optimum performance of business refrigeration systems. By adhering to a proactive upkeep schedule, organizations can reduce the risk of pricey malfunctions, prevent downtime, and prolong the life-span of their refrigeration tools.

One important preventative maintenance method is regular cleaning of condenser coils. Gradually, these coils can collect dust, particles, and dirt, which can restrain warm transfer and reduce the system's performance. By cleaning the coils regularly, businesses can make sure that the refrigeration system runs at peak performance.

In addition, checking and replacing used gaskets on doors is another vital upkeep task. Damaged gaskets can cause air leakages, causing the refrigeration system to function tougher to maintain the preferred temperature level. By changing defective gaskets immediately, organizations can improve energy effectiveness and lengthen the life of the equipment.

Incorporating these preventative maintenance techniques right into a comprehensive maintenance plan can Check This Out assist organizations optimize the performance and reliability of their industrial refrigeration systems.

Expert Fixing Vs. DO IT YOURSELF: Cons and pros

Engaging a professional repair work solution for commercial refrigeration systems supplies distinct benefits over attempting DIY repair work. Commercial refrigeration units are intricate systems that call for specialized understanding and skills to diagnose and fix successfully.

Additionally, expert repair solutions commonly supply warranties on their job, providing you comfort knowing that the work is ensured. Attempting to fix a commercial refrigeration system on your own can helpful hints cause further damages if not done correctly, possibly resulting in even more expensive repairs down the line. In addition, DIY fixings may void any kind of existing guarantees on the tools, leaving you exclusively in charge of any future concerns that may develop. While DIY fixings may appear affordable originally, the long-lasting advantages of expert repair work solutions outweigh the dangers and unpredictabilities connected with trying fixings on your own.

Final Thought

To conclude, understanding common industrial refrigeration problems, having the crucial tools for repair work, complying with a detailed troubleshooting overview, and applying preventative upkeep strategies are key components of maintaining and repairing commercial refrigeration systems. While expert repair service solutions might supply competence and effectiveness, do it yourself repair services can additionally be a cost-effective choice for those with the needed abilities and understanding. Inevitably, regular maintenance and prompt repair work are vital for ensuring the proper performance of commercial refrigeration systems.

Comprehending the crucial actions for business refrigeration repair service and being able to recognize common issues are important skills for any organization proprietor or maintenance personnel. In this comprehensive overview, we will certainly explore the fundamental actions and typical issues in business refrigeration fixing, furnishing you with the knowledge required to resolve these difficulties efficiently.

Engaging a specialist repair work service for business refrigeration systems uses unique advantages over trying DIY repair work. Trying to repair a commercial refrigeration system on your own can lead to further damages if not done properly, potentially resulting in even more expensive repairs down the line.In final thought, understanding usual industrial refrigeration issues, having the important tools for repair work, complying with a detailed troubleshooting overview, and implementing preventative upkeep techniques are essential components of preserving and fixing commercial refrigeration systems.

Report this page